Breakthrough Innovations

in Mineralized Resin Coatings for Sustainable Packaging Materials

The Magic of

Mineralized Resin Coatings

for Barrier-coated Paper Packaging

with Less Plastic

and Designed for Recycling in

All Conventional Paper Recycling Systems

The next generation in mineralized resin technology

HyperBarrier is a ternary nanocomposite with 20x improvement for oxygen barrier and 15x improvement for moisture barrier over conventional polyethylene coatings

Applications

Rigid Paper Packaging

Paper Cups, Takeout Trays, Folding Cartons

Flexible Paper Packaging

Pouches, Bags, Sacks, Sachets

The Sustainability Challenge with Barrier-Coated Paper Packaging

Paper-based packaging with barrier coatings such as polyethylene and other biopolymers are notoriously difficult to recycle, leading to much of this packaging winding up in landfills. When conventional plastic-coated packaging is recycled in conventional paper recycling systems, the plastic coating breaks down into large sturdy flakes that can clog the screening process and can damage equipment. So, the materials are undesirable and typically sorted to landfills.

The Sustainable Solution

By mineralizing the resin, by up to 51%, the coating acts like a resin coating for the purposes of packaging performance, while acting as clay coating for the purposes of recycling. All paper recycling systems are designed for handle clay coatings, making this a universal solution for today’s paper recycling infrastructure. Industry recycling tests have categorized EarthCoating as a clay coating, not a polymer coating, therefore paper packaging with EarthCoating qualifies for collection in the premium uncoated paper category.

Over 2.5 billion packages with EarthCoating have been sold to date globally.

Packaging with EarthCoating has been recycled in conventional paper recycling systems with the RecycleMe collection program to be made into gift wrap for Hallmark and copy paper for Australian Paper, and sold through KMart.

Did you know?

Plastic-coated paper packaging such as paper cups, take-out boxes, and food wraps are not compatible with paper recycling systems and are typically sent to the landfill.

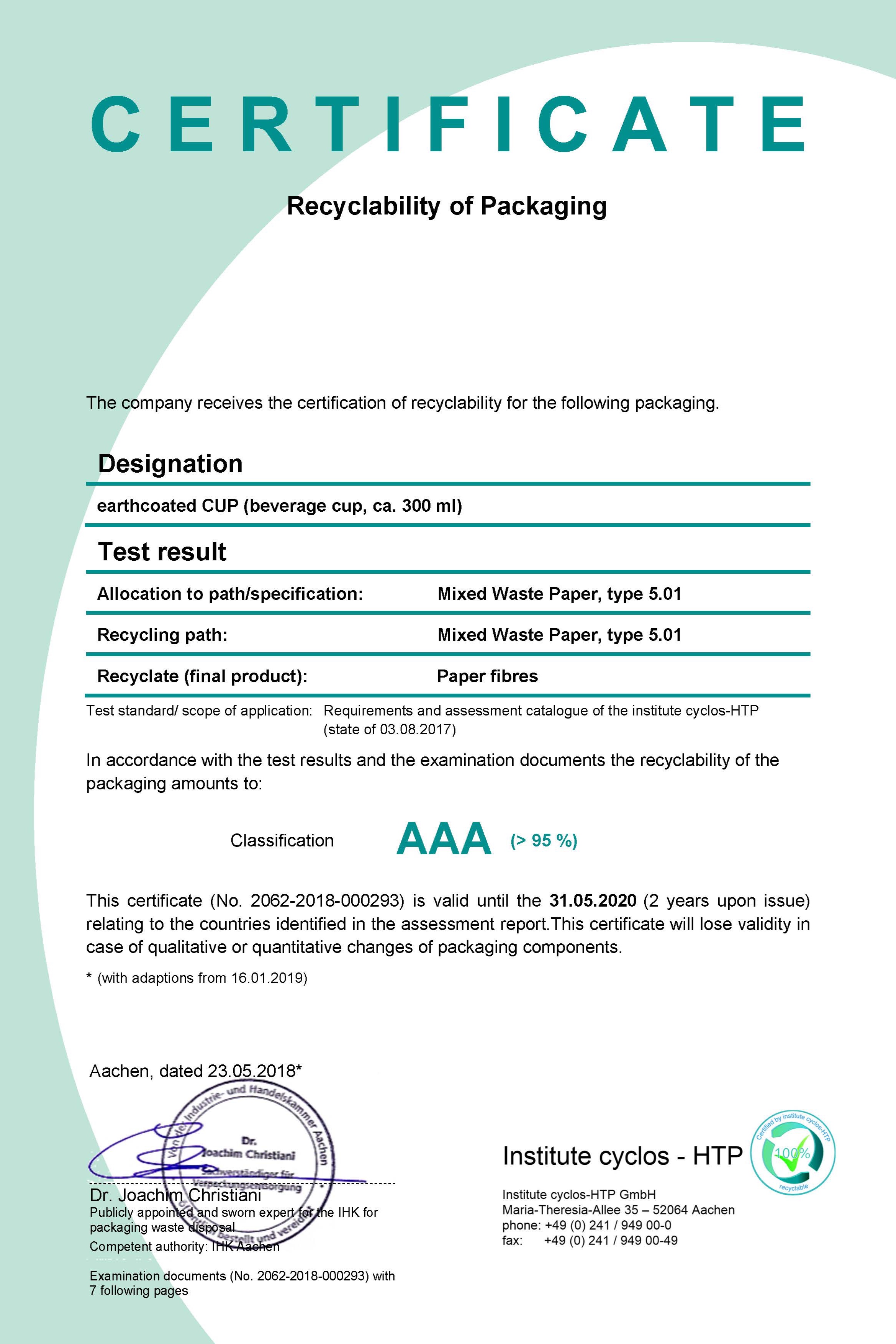

An overview of the Repulpability and Recyclability of paperboards with EarthCoating®

The graphic to the left illustrates the process of paper recycling. A major part of the process includes extracting and cleaning fibers from non-paper contaminants that can found in the recycled paper stream. Unlike traditional plastic coatings, EarthCoating® is engineered for efficient processing in recycling systems. EarthCoating® is designed to fracture into small, dense particles in the pulping process, thereby avoiding the challenges found with traditional plastic coatings.

We’ve recently added additional content to our repulpability report and will continue to update our data as new information becomes available.

Recycled Paper Products Made From Recycled Packaging with EarthCoating

Paper cups made with EarthCoating

qualify for collection in Path 13,

the premium uncoated paper

recycling stream (Cyclos HTP)

AAA Rating for Recyclability

Mineralized EarthCoating® Revolutionizes Paper Cup Recycling

This short explainer video shows paper cups made with EarthCoating® (branded as RecycleMe in Australia) being pulped back into recycled paper using conventional paper recycling equipment.

Paper cups in Australia have been recycled into gift wrap for Hallmark and copy paper for Australian Paper

Paper Cups with EarthCoating are fully compatible with paper recycling systems

Paper cups with EarthCoating can be added into the pulping system as if they are uncoated paper materials, to make premium paper products.

In contrast, conventional paper cups with 100% plastic coatings are typically sorted out to landfill, or diluted to comprise no more than 3% of the mix in a pulper, otherwise they may cause shutdown, or damage paper recycling equipment

A Day In The Life of a RecycleMe™ Cup

RecycleMe™ paper cups are made with EarthCoating® and are designed to be valuable and easy for paper recyclers to process them back into copy paper after use.

To learn more, visit RecycleMe.

Recycling in Ireland

reCUP Paper cups are made with EarthCoating® and are fully compatible with conventional paper recycling systems in Ireland and UK, without specialized equipment or the need for specialized collection. To learn more, visit CupPrint

Recycling in UK

RecycleMe™ paper cups are made with EarthCoating® and are being recycled in closed-loop collection program in partnership with the Shredall Group.

To learn more, visit RecycleMe.

Planet Ark endorses RecycleMe™

The RecycleMe™ closed-loop paper cup collection system has received an official endorsement from Planet Ark.

RecycleMe™ paper cups are made with EarthCoating®